THE EFFECTIVENESS OF EUROPEAN PROJECTS AND INTERNATIONAL PARTNERSHIPS: SOME ACHIEVEMENTS

BAM stand at Hannover Messe 2019. Source: BAM

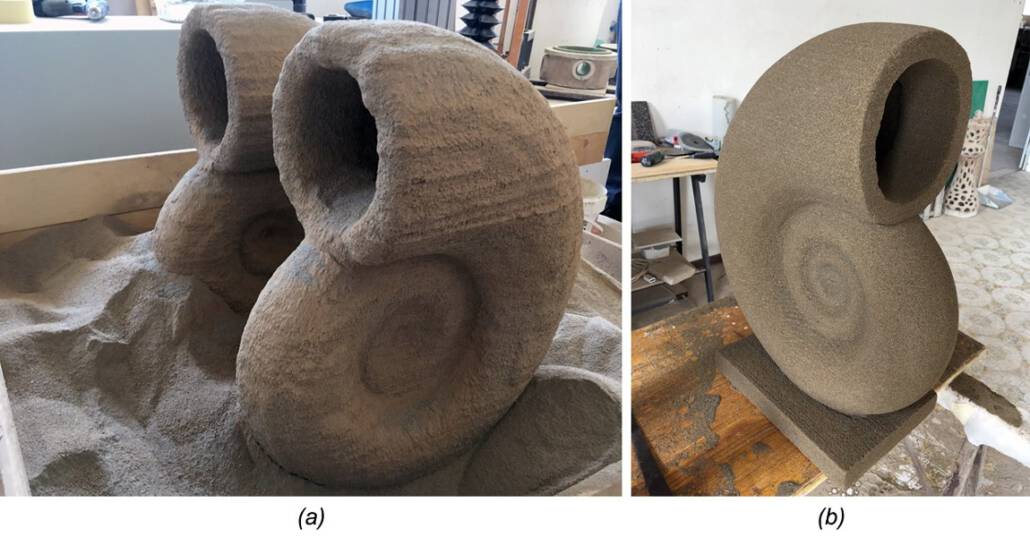

Once again the results are not long in coming: two 3D printed prototypes, born from the partnership between Desamanera and BAM, the German federal research center, within the AMITIE project, were on display at the Hannover Messe 2019 where in recent days the numerous visitors have seen them in person and touched their complexity.

The Hannover Messe is one of the most important worldwide showcases in the field of innovation and new technologies: every year it welcomes international exhibitors ranging from R&D to industrial automation, from IT to Energy and Environment Technology, and counts more than 200,000 visitors per edition, from all over the world. This year the fair took place from 1 to 5 April and focused on digital and industrial transformation,with the aim of promoting an interconnected, automated and global industry.

The research project that involves us is only one of the four presented at the international fair by BAM. Acronym of the German Bundesanstalt für Materialforschung und -prüfung, that means Federal Institute for research and testing of materials, BAM is the research center led by the German Ministry of Economy and Technology, whose mission is to improve the safety of chemistry, technology and materials, through research and development activities, tests, analyses, issue of permits, advices and information. The collaboration between BAM and Desamanera is solid long before now, born thanks to the AMITIE project and already witnessed in this article, written when Prof. Jens Günster and his team spent three weeks working in our laboratory.

The AMITIE project, which began in 2017 and is funded by the EU Horizon 2020 with the Marie Skłodowska Curie Actions, has the objective of promoting research and innovation in the sector of Additive Manufacturing of Ceramic materials through a program of international and intersectoral staff exchanges between the partner companies.

Engineer Filippo Gobbin, Antonino Italiano, Prof. Jens Günster, Prof. Paolo Colombo and our Indian Girl, 2016.

That was the first time Prof. Günster has been in Desamanera headquarters

The team of Prof. Jens Günster, Director of the Ceramic Processing and Biomaterials division at BAM, took the opportunity of the Hannover Messe to disseminate to the world of industry and to the public the results achieved so far by the research project on 3D printing of components in cement, concrete and ceramic materials. The two prototypes on display were made through the additive manufacturing technologies for minerals of Desamanera and, with their complex shapes, represent a new opportunity to efficiently produce unique, custom-made, large-sized stone elements and small series of personalized elements.

The traditional methods for producing concrete and cement elements offer limited shape possibilities and, in the case of complex structures, they incur expensive and difficult to implement solutions. In particular, Prof. Günster concentrated on the development and production of some infrastructural elements of unique and complex shapes that make up the hydraulic and sewer underground systems, such as water collectors and diversions, pipes, joints, fittings. These components, like any other infrastructural part, require periodic maintenance, repairs and replacements; but due to their specific shape the necessary operations are often expensive and time-consuming.

The new additive manufacturing technologies are particularly suitable for solving similar production problems in a new efficient way, faster and with lower costs, also when they occur outside of this operating – application sector.

The artworks shell-shaped: just after printing and still inside the bed-powder (a); after post-production phase (b).

VIDEO: Schwarz P, geometric shape representing a “minimal surface”.

Prof. Günster himself states that “Additive manufacturing is already utilised for plastic and metals with great success […] We want to further develop the manufacturing process so that it can also be safely applied in the construction materials sector”.

On this page you can learn more about this project, while on this you can find information about AMITIE, the EU H2020 funded project that made it possible.

Published on 13th April 2019